1.Good quality wood selection

A log house can be built of various kinds of wood. In our country we use mostly wood of coniferous trees (spruce, fir, pine, red spruce). Selection of the right material is the first key step towards a high quality log house. Many producers recommend winter felling (January - March) The trees should grow in the altitude of at least 800 m above sea level. Our log houses are made of trunks with a central diameter from 30 cm to 45 cm. Logs must be healthy, free of cracks and, most importantly, they must have minimal convergence.

2 Preparation of logs

After the logs are bought to the production plant, the bark is removed manually. Right after removing the bark, the wood needs chemical treatment against wood-destroying insects, moulds and fungi, because after debarking, fragrant essences are released into the air attracting insects. Then, the logs are stored for natural drying.

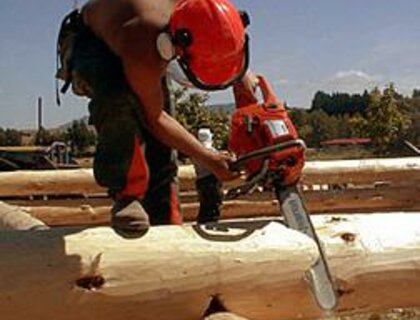

3.Assembly of the log frame within the production plant

Every log structure is always assembled in our production plant first during so called practice assembly. The debarked logs are drawn on with a special woodworking compass – this requires skill, time and expertise. The production of a 10 x 8 m log frame takes about 6-8 weeks and the assembly of the truss 1 to 2 weeks.

4.The log house transport and assembly

After the customer’s approval, the electrical installation is marked and all logs are numbered. After being brought to the construction site, sheep fleece and sealing tapes are placed in the lengthwise grooves and pins. A fire protection for electrical wiring is installed in the log walls. The logs are placed one by one by a crane according to their numbers. Then the truss structure is mounted onto the frame, the gable walls assembled and the roofing is laid.